Описание

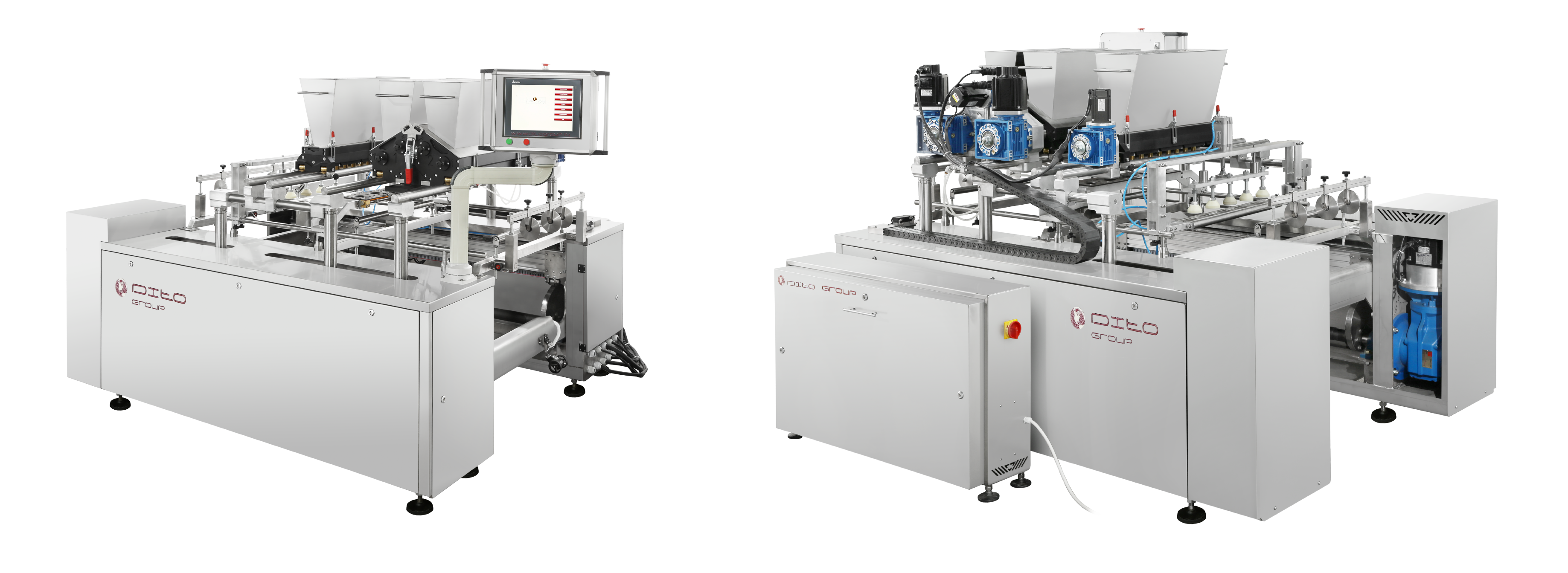

9 row universal most modern dough dropping machine

designed for the production of cookies, gingerbread, meringue, biscuit cakes, custard

products in the widest range and forms with and without filling (depending on the type and

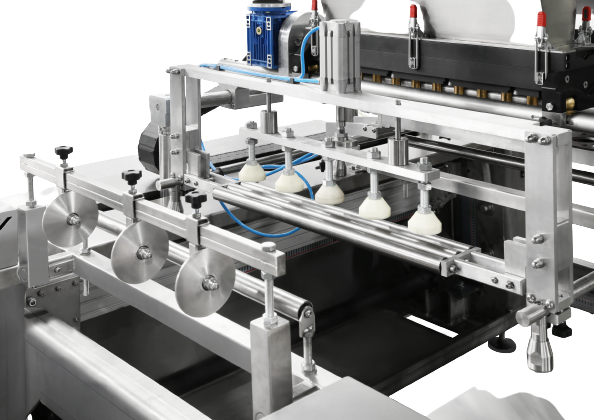

test recipes). A wide choice of nozzles, makes it possible to produce both one, two-color products with jam both on top and inside in the form of a filling.

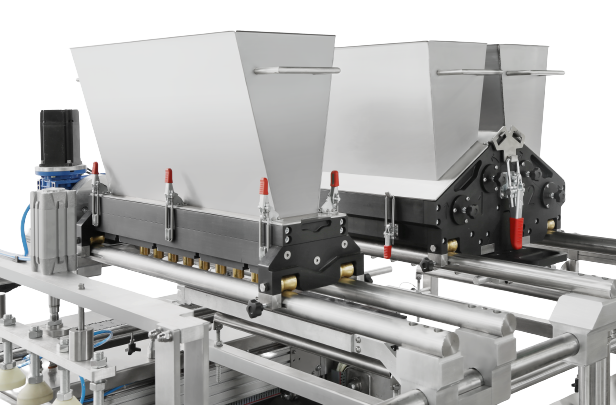

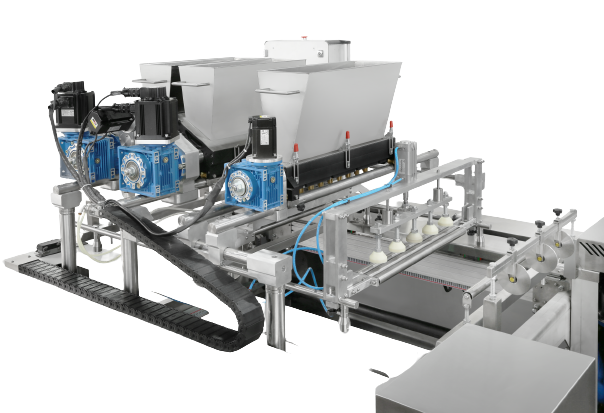

A feature of the machine is the installation on the basic version of various dosing

heads. A modern digital system with software will allow you to

it is convenient to control both the movement of the trays and the types of dosing. From point to rotating and various lengths. On this machine, you can always expand

product range by purchasing new nozzles or dosing

heads. The machine is made of AISI 304 stainless steel.