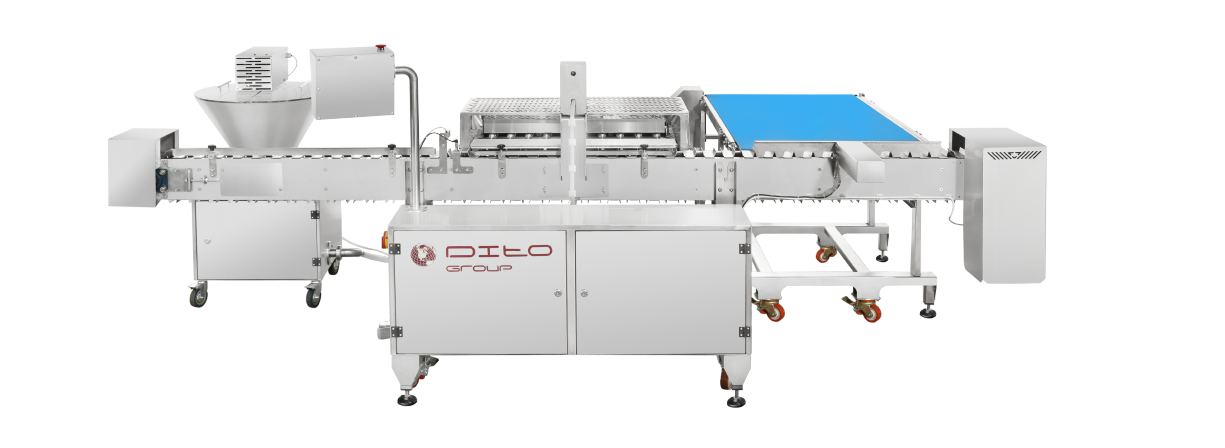

HORIZONTAL DOSING LINE D10

BENEFITS

•The machine is made entirely of AISI 304 stainless steel.

•Dosing head with 4 outlets, filled with vertical screws.

•Production speed with "drip" injection: about 2400/4000 pieces/hour.

•Production speed with "linear" injection: variable according to the length of the injection line of the product: about 1200/2500 pieces/hour.

•Needle control: mechanical, with independent 0.37kW motor with control sensor and electronic inverter.

• Conveyor belt control: 0.37 kW independent motor, with control sensor and electronic inverter.

•Detector with photocell to detect products to be injected.

•Loading hopper: maximum capacity 50 liters.

• Needles for injection: diameter 6 mm. (it is possible to manufacture according to the customer's specification)

•Protective panels made entirely of AISI 304 stainless steel.

•Products are unloaded using a linear pusher driven by a pneumatic cylinder.

•The control panel is completely made of AISI 304 stainless steel and allows you to control the functions of the machine, the control system uses a PLC and an Omron touch display, as well as various stored programs.

•Fill management system and product availability.

•Horizontal and vertical possibility of dispensing the product.

• Easy line cleaning (15 min)

•Possibility of accurate and easy regulation of the quantity of products and the continuity of their flow.